Rectangular Duct Applications

(Full OPM)

1) Duct Connection

Option 1: Sheet Metal Screws

(2) #10 Sheet Metal Screws thru strut and duct walls at each corner

1" O.C. and 1" Max from edge, each corner, Typ

Use solid channel for horizontal members if using this option

Approved Sheet Metal Screws (#10 Size):

- ITW Buildex (ESR-1976 & ESR 3223)

- Simpson Strong-Tie (ESR-3006)

- Darts (ER-5202)

- Elco (ESR-3294)

- Hilti (ESR-2196)

Option 2: Weld

Only for Duct 18 ga. and thicker

Start from Duct edge, each corner, Typ

Flare-bevel field weld, both sides

2" long

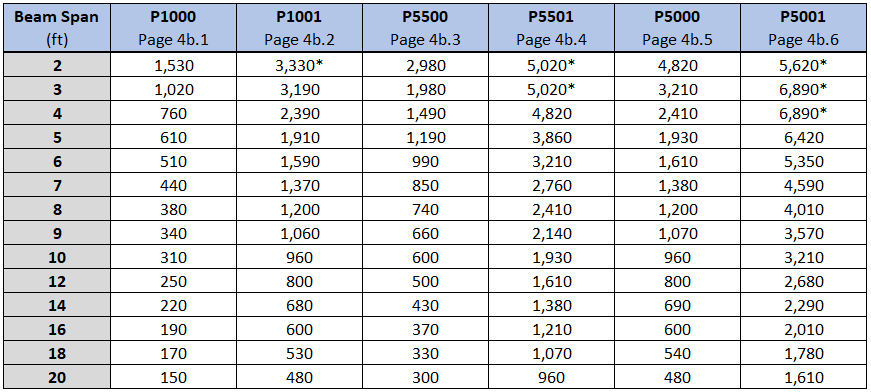

2) Horizontal Beams

Maximum Allowable Uniform Vertical Load per Beam (lbs)

Notes:

1. Values in this table apply only to Unistrut brand products. Unistrut channels are stamped with the name "UNISTRUT".

2. Values in this table are valid with all solid, T, WT and HS pierced channels of the above channel profiles.

3. * Load is limited by spot weld shear. Weld shear and tension are accounted for in the above listed capacities.

4. Refer to OPM Page 4b.0 for the detailed calculation procedure.

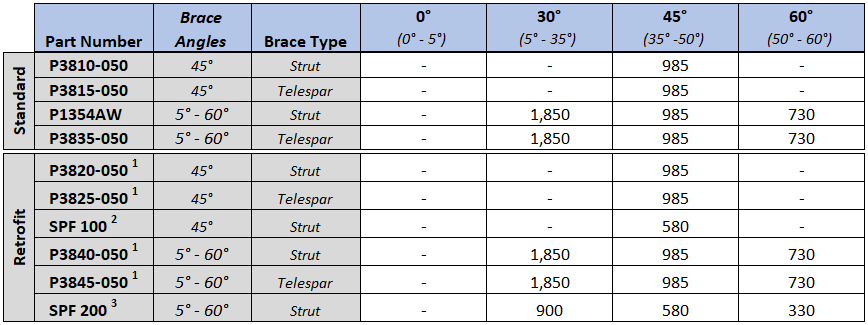

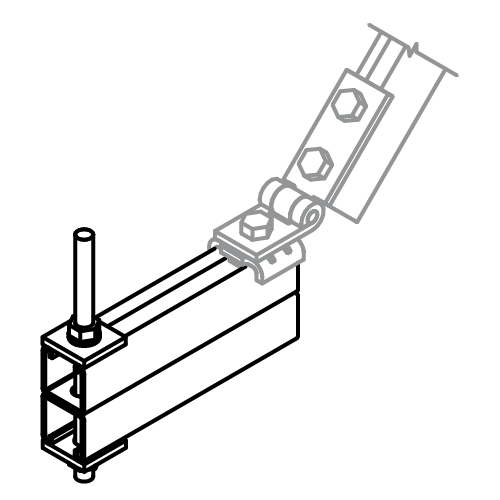

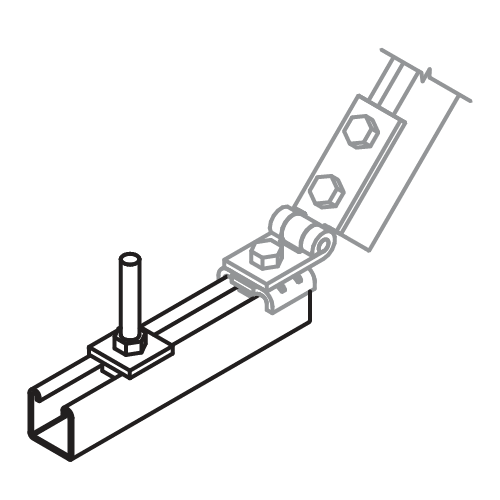

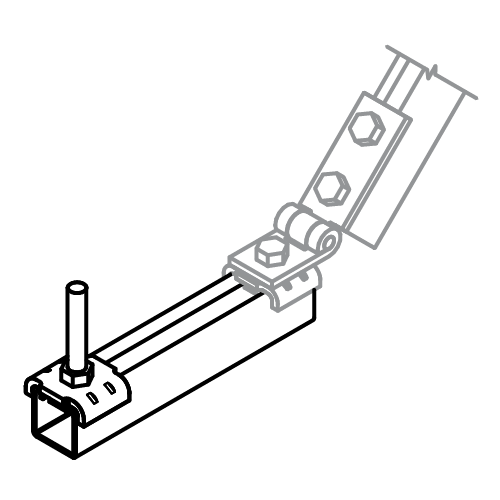

3) Brace Member

Maximum Horizontal FP Force (lbs) [ASD] at 45° from Horizontal

Notes:

1. Values in this table apply only to Unistrut brand products. Unistrut channels are stamped with the name "UNISTRUT".

2. Values in this table are valid with all solid, T, WT and HS pierced channels of the above channel profiles.

3. These brace members are valid for angles from 0° to 60° from horizontal. Refer to product or OPM pages for capacities.

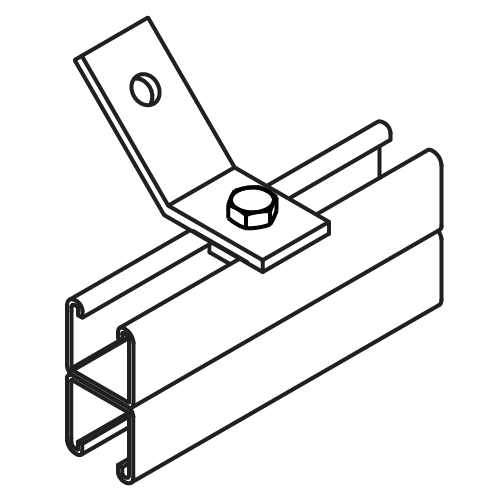

4) Brace Fitting

FP Load Capacity (lbs)

Notes:

- Use with P3860 base.

- Use with LS 100 base.

- Use with LS 200 base.

- All angles above are from horizontal. All loads are based on use with a 1/2" or larger fastener and connected per one of the connection details outlined below.

5) Connection Details

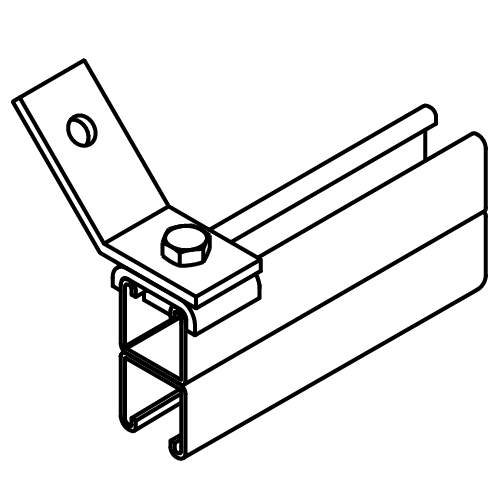

Brace Bolted to Channel

3" Min. End Distance

Brace Bolted to Channel

Flush to End

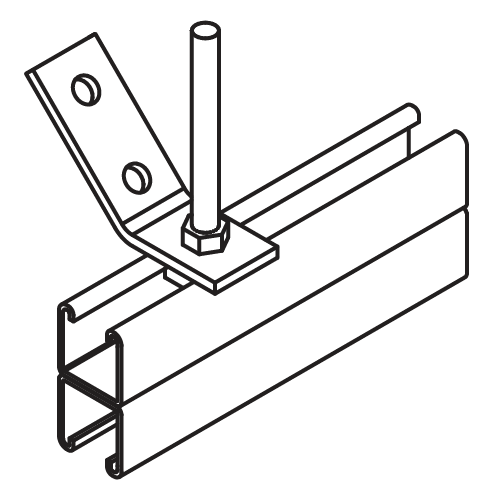

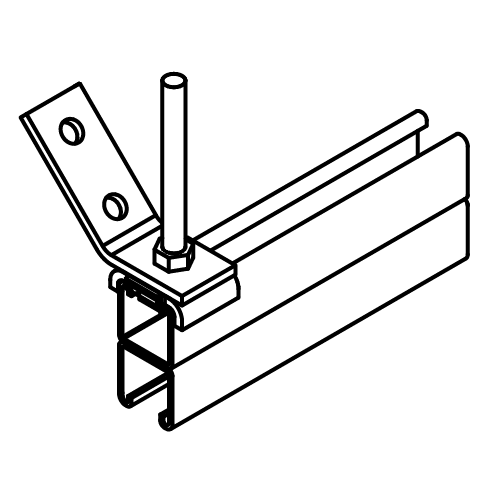

Brace Around Rod to Channel

3" Min. End Distance

Brace Around Rod to Channel

Flush to End

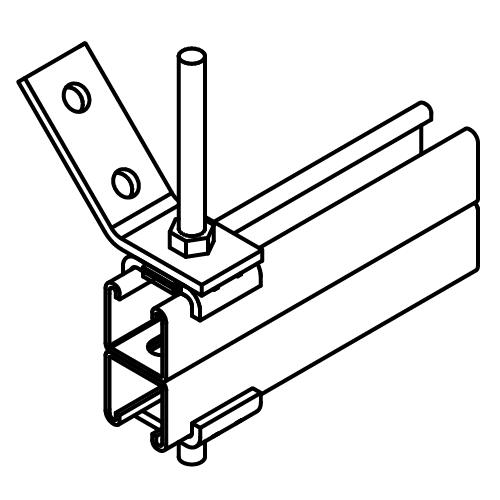

Brace Around Rod Thru Channel

1-1/2" Min. End Distance

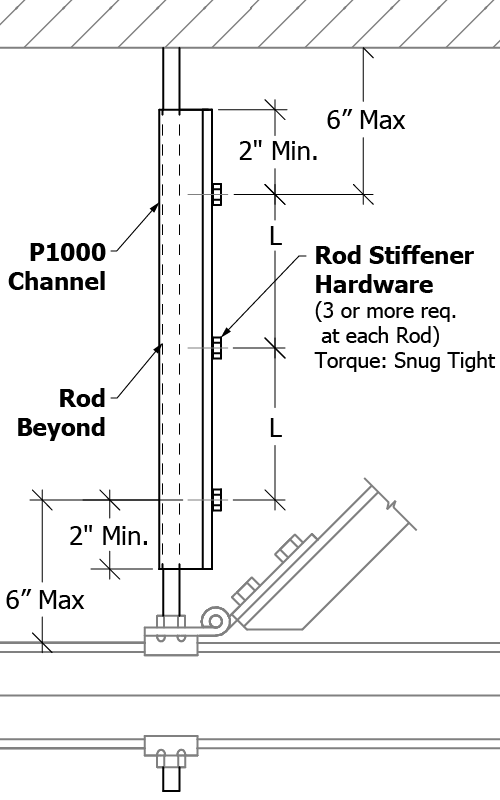

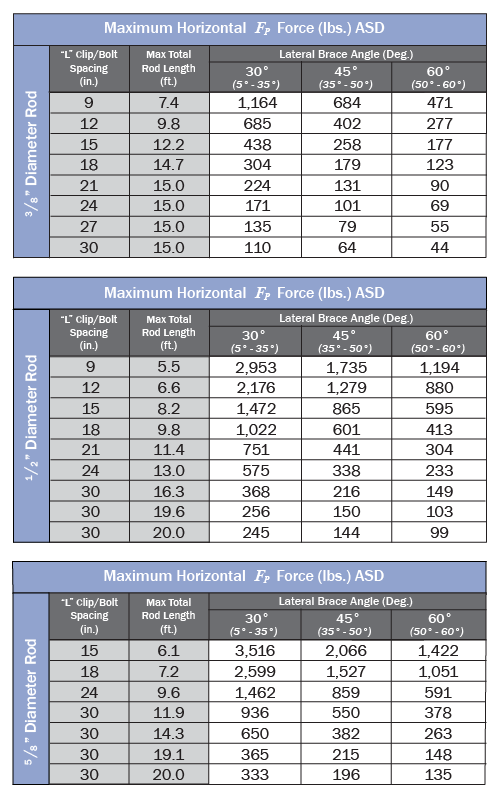

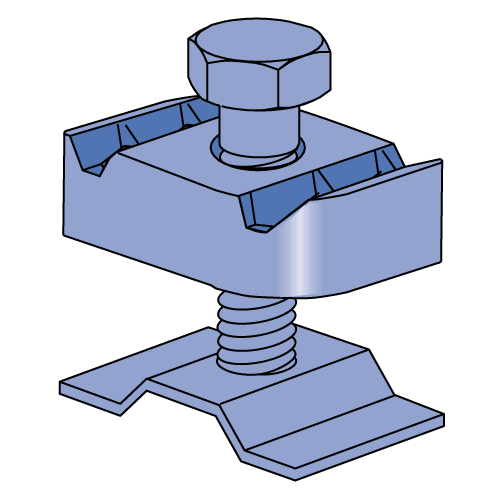

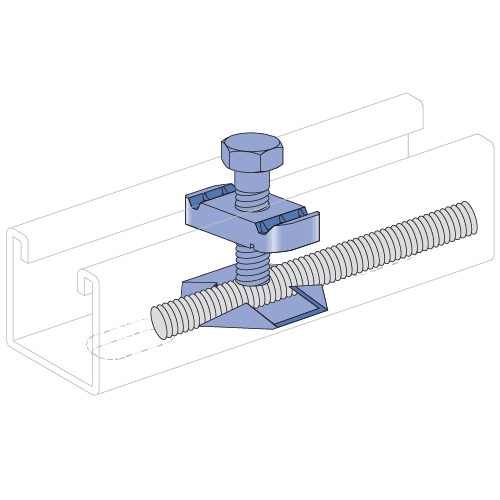

6) Rod Stiffeners