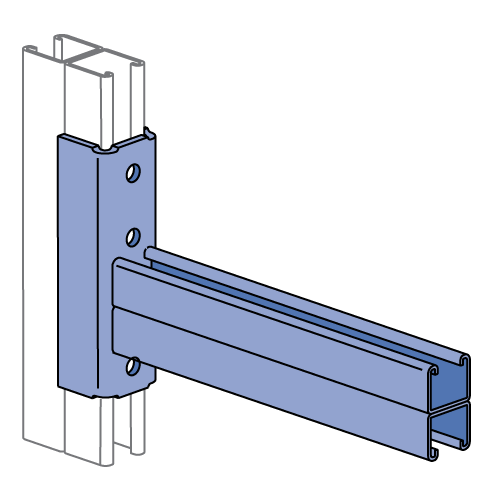

P2580 - 12" to 36" Heavy Duty Bracket (Slots Up and Down) (1-5/8" Series)

35% Stronger than competitive products! Highest Capacity in the Market!

Features & Benefits:

- 35% stronger than competitive products!

- Uses a 3-bolt attachment and a U-shaped base plate for added strength

- Double-sided channel allows attachment on top and bottom

- Made in America

- Patent Pending

Standard Dimensions:

- Hole Diameter: 9/16" (14mm)

- Hole Spacing (From End): 13/16" (21mm)

- Hole Spacing (On Center): 1-7/8" (48mm)

- Width: 1-5/8" (41mm)

- Channel Thickness: 12 Gauge

- Fitting Thickness: 1/4"

- Material: ASTM A1011 SS GR 33

Note: When used for mechanical supports, load capacities of brackets and fittings should be in compliance with the American Standard Code for Pressure Piping.

The New Heavy Duty Bracket: P2580-XX

Unistrut is proud to introduce the new heavy duty bracket, P2580-XX. This new bracket features a clevis shaped base and 3-bolt attachment for added strength, length options from 12" to 36", and has double-sided channel for top and bottom attachments.

A Competitive Overview

The Cantilever Bracket - Double Strut is commonly used for pipe, cable tray, conduit and equipment supports for both top and bottom attachment. Many manufacturers make a similar item to ours, with similar capacities.

The P2580-XX features the following expanded load capacities:

| NEW | |||

|

|

||

| Length | Unistrut P2580-XX |

Competitive Brackets | Strength Increase |

| 12" | 2,700 | 1,621 - 2,000 | 35% - 66% |

| 18" | 1,800 | 1,050 - 1,300 | 38% - 71% |

| 24" | 1,350 | 800 - 1,000 | 35% - 68% |

| 30" | 1,080 | 650 - 800 | 35% - 66% |

| 36" | 900 | 500 - 650 | 38% - 80% |

Capacities listed above are in pounds.

Application Examples

Pipe and Conduit Supports

Old with Pipe & Conduit

Supporting two 8" Schedule 40 Water Filled Pipes

- Total Weight: 101 lbs./ft.

- Bracket Capacity (24"): 1,000 lbs.

- Max. Span: 9.9 ft.

This 40' run requires 5 supports!

NEW with Pipe & Conduit

Supporting two 8" Schedule 40 Water Filled Pipes

- Total Weight: 101 lbs./ft.

- Bracket Capacity (24"): 1,350 lbs.

- Max. Span: 13.4 ft.

This 40' run requires only 4 supports!

- Save 35% on labor for installation of supports

- Save over 15% on support materials

Cable Tray Supports

Old with Cable Tray

This requires 3 supports per straight!

Supporting an 18" Wide NEMA Class 20C System

- Cable Weight: 100 lbs/ft x 20 ft = 2,000 lbs

- Tray Weight: 4 lbs/ft x 20 ft = 80 lbs

- Total Weight: 2,080 lbs

- Bracket Capacity (24"): 1,000 lbs

- Supports Needed: 2,080 lbs / 1,000 lbs = 2.08

- Requires 3 supports

NEW with Cable Tray

This requires only 2 supports per straight. Save 33% on labor for installation of supports and save over 20% on support materials!

Supporting an 18" Wide NEMA Class 20C System

- Cable Weight: 100 lbs/ft x 20 ft = 2,000 lbs

- Tray Weight: 4 lbs/ft x 20 ft = 80 lbs

- Total Weight: 2,080 lbs

- Bracket Capacity (24"): 1,350 lbs

- Supports Needed: 2,080 lbs / 1,350 lbs = 1.54

- Requires only 2 supports

| Part No. | Nom. Pipe Size | Finish | Product Weight / Piece (lbs) |

|---|---|---|---|

| P2580-12 | 12" | HG | 6.1 |

| P2580-12 | 12" | GR | 6.1 |

| P2580-12 | 12" | SS | 6.1 |

| P2580-18 | 18" | HG | 7.8 |

| P2580-18 | 18" | GR | 7.8 |

| P2580-18 | 18" | SS | 7.8 |

| P2580-24 | 24" | HG | 9.5 |

| P2580-24 | 24" | GR | 9.5 |

| P2580-24 | 24" | SS | 9.5 |

| P2580-30 | 30" | HG | 11.2 |

| P2580-30 | 30" | GR | 11.2 |

| P2580-30 | 30" | SS | 11.2 |

| P2580-36 | 36" | HG | 12.9 |

| P2580-36 | 36" | GR | 12.9 |

| P2580-36 | 36" | SS | 12.9 |

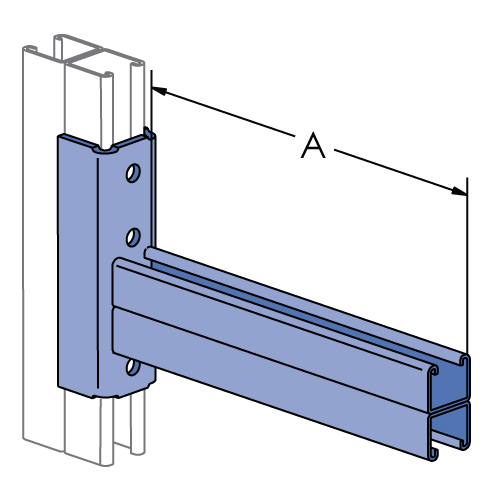

Design Loads

| Design Loads - P2580 | ||

|---|---|---|

| Part Number | Length "A" |

Uniform Design Load* lbs (kN) |

| P2580-12 | 12" | 2,700 (12.00) |

| P2580-18 | 18" | 1,800 (8.00) |

| P2580-24 | 24" | 1,350 (6.00) |

| P2580-30 | 30" | 1,080 (4.80) |

| P2580-36 |

36" | 900 (4.00) |

Notes:

- Design loads only apply to Unistrut brand products. Look for "UNISTRUT" on the part.

- * Safety factor = 2.5 based on the ultimate strength of the connection when mounted to 12 gauge channel.

General Specifications

Standard Dimensions (Unless Shown Otherwise on Drawing):

- Hole Diameter: 9/16" (14mm)

- Hole Spacing (From End): 13/16" (21mm)

- Hole Spacing (On-Center): 1 7/8" (48mm)

- Width: 1 5/8" (41mm)

- Thickness:

- 1/4" (6.4mm) with steel meeting or exceeding ASTM A1011 SS GR 33, or

- 0.220" (5.6mm) with steel meeting or exceeding ASTM A1011 HSLAS GR 45

Note:

- When used for mechanical supports, load capacities of brackets and fittings should be in compliance with the American Standard Code for Pressure Piping.

Materials & Finishes

Materials & Finishes - Standard:

- Base Metal: Steel conforms to ASTM A1011 SS GR 33, A1011 HSLAS GR 45, A36, A575, A576, or A635.

- Electrogalvanized (EG): Conforms to ASTM B633, Type III SC1

- Unistrut Defender (DF): Conforms to ASTM A1059

- Hot Dip Galvanized (HG): Conforms to ASTM A123 or A153

- Perma-Green (GR): Conforms to commercial standards for powder coating

- Perma-Gold (ZD): Conforms to ASTM B633, Type II SC1 or SC3

- Plain (PL): No finish

Materials & Finishes - Special Metals:

- Stainless Steel, Type 304 (SS): Conforms to ASTM A240 or A276, Type 304 *

- Stainless Steel, Type 316 (ST): Conforms to ASTM A240 or A276, Type 316 *

- Aluminum (AL): Conforms to ASTM B209, Type 1100F or 5052-H32 *

* These materials have different physical properties and performance characteristics. Please contact us for design support.