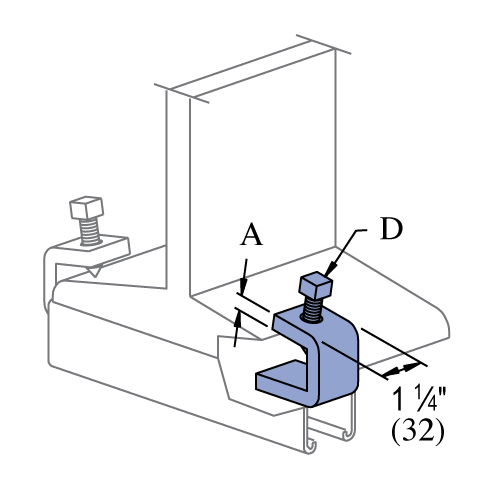

P1272S, P1985S & P1986S - Beam Clamp (1-5/8" Series)

| Part No. | Nom. Pipe Size | A | D | Finish | Flange Thickness | Product Weight / Piece (lbs) |

|---|---|---|---|---|---|---|

| P1272S | Up to 3/4" | 1/4" (6) | 3/8"-16 x 1-1/2" | EG | Up to 3/4" (Up to 19mm) | 0.39 |

| P1272S | Up to 3/4" | 1/4" (6) | 3/8"-16 x 1-1/2" | HG | Up to 3/4" (Up to 19mm) | 0.413 |

| P1272S | Up to 3/4" | 1/4" (6) | 3/8"-16 x 1-1/2" | GR | Up to 3/4" (Up to 19mm) | 0.39 |

| P1985S | Up to 3/4" | 3/8" (10) | 1/2"-13 x 1-1/2" | EG | Up to 3/4" (Up to 19mm) | 0.62 |

| P1985S | Up to 3/4" | 3/8" (10) | 1/2"-13 x 1-1/2" | HG | Up to 3/4" (Up to 19mm) | 0.657 |

| P1985S | Up to 3/4" | 3/8" (10) | 1/2"-13 x 1-1/2" | GR | Up to 3/4" (Up to 19mm) | 0.62 |

| P1986S | 7/8" to 2" | 3/8" (10) | 1/2"-13 x 1-1/2" | EG | 7/8" to 2" (22mm - 51mm) | 0.83 |

| P1986S | 7/8" to 2" | 3/8" (10) | 1/2"-13 x 1-1/2" | HG | 7/8" to 2" (22mm - 51mm) | 0.88 |

| P1986S | 7/8" to 2" | 3/8" (10) | 1/2"-13 x 1-1/2" | GR | 7/8" to 2" (22mm - 51mm) | 0.83 |

Design Loads & Installation

| Design Loads - P1272S, P1985S & P1986S | ||

|---|---|---|

| Part Number | "A" in (mm) |

Design Load Per Pair (Use in Pairs Only) lbs (kN) |

| P1272S | 1/4" (6.4) | 450 (2.00) |

| P1985S | 3/8" (9.5) | 1,000 (4.45) |

| P1986S | 3/8" (9.5) | 900 (4.00) |

Notes:

- Design loads only apply to Unistrut brand products. Look for "UNISTRUT" on the part.

- Use in pairs only.

- Safety factor = 2.5 based on ultimate strength of connection.

- Set Screw "D" is supplied with this part.

- Set Screw Installation Torque:

P1272S: 60 in-lbs (7 N-m)

P1985S & P1986S: 125 in-lbs (14 N-m)

Seismic Design Loads

| P1985S Allowable (Design) Loads (lbs) |

||

| Pullout | Slip Along | Slip Thru |

| 1,000 | 900 | 500 |

Notes:

- Design loads only apply to Unistrut brand products. Look for "UNISTRUT" on the part.

- Seismic design loads are for the P1985S part only and for the 2 clamp installation as shown above.

- Must use clamps in pairs as shown above.

- Design loads are based on static testing with a safety factor = 5 based on ultimate strength of connection.

- Set Screw Installation Torque: 125 in-lbs (14 N-m)

General Specifications

Standard Dimensions (Unless Shown Otherwise on Drawing):

- Hole Diameter: 9/16" (14mm)

- Hole Spacing (From End): 13/16" (21mm)

- Hole Spacing (On-Center): 1 7/8" (48mm)

- Width: 1 5/8" (41mm)

- Thickness:

- 1/4" (6.4mm) with steel meeting or exceeding ASTM A1011 SS GR 33, or

- 0.220" (5.6mm) with steel meeting or exceeding ASTM A1011 HSLAS GR 45

Note:

- When used for mechanical supports, load capacities of brackets and fittings should be in compliance with the American Standard Code for Pressure Piping.

Materials & Finishes

Materials & Finishes - Standard:

- Base Metal: Steel conforms to ASTM A1011 SS GR 33, A1011 HSLAS GR 45, A36, A575, A576, or A635.

- Electrogalvanized (EG): Conforms to ASTM B633, Type III SC1

- Unistrut Defender (DF): Conforms to ASTM A1059

- Hot Dip Galvanized (HG): Conforms to ASTM A123 or A153

- Perma-Green (GR): Conforms to commercial standards for powder coating

- Perma-Gold (ZD): Conforms to ASTM B633, Type II SC1 or SC3

- Plain (PL): No finish

Materials & Finishes - Special Metals:

- Stainless Steel, Type 304 (SS): Conforms to ASTM A240 or A276, Type 304 *

- Stainless Steel, Type 316 (ST): Conforms to ASTM A240 or A276, Type 316 *

- Aluminum (AL): Conforms to ASTM B209, Type 1100F or 5052-H32 *

* These materials have different physical properties and performance characteristics. Please contact us for design support.