P1100HS - 1-5/8" x 1-5/8", 14 Gage, Round Holes

Unistrut's P1100HS has round holes on the back side for use with 1/2" threaded rod and fasteners. These holes can eliminate the need for field drilling when installing a trapeze support, anchoring the channel to a surface, or for many other applications.

This channel is commonly used for trapeze supports, seismic bracing, and anchoring to floors, ceilings and walls. This is a great product for certain seismic bracing applications where slots are not allowed.

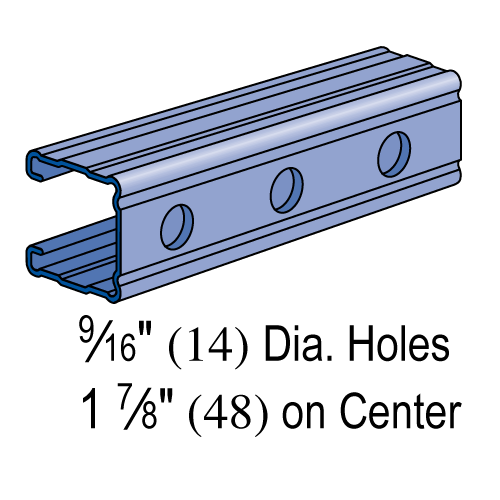

Product dimensions are 1 5/8" wide x 1 5/8" tall x 14 ga. thick; with round holes on one side. The holes are 9/16" in diameter and 1 7/8" on center. The hole diameters and spacing match Unistrut’s general fittings so that nearly all our fittings can be attached through these holes.

Our P1100HS is available in the following finishes: Pre-Galvanized (PG), Hot-Dip Galvanized (HG), Plain (PL), Green (GR), Zinc Dichromate (ZD), Stainless Steel (SS) and Aluminum (EA).

| Part No. | Length (ft) | Finish | Product Weight / Ft (lbs/ft) |

|---|---|---|---|

| P1100HS | 20 | PG | 1.36 |

| P1100HS | 10 | PG | 1.36 |

| P1100HS | 10 | HG | 1.442 |

| P1100HS | 20 | HG | 1.442 |

| P1100HS | 20 | GR | 1.36 |

| P1100HS | 10 | GR | 1.36 |

| P1100HS | 20 | PL | 1.36 |

| P1100HS | 10 | PL | 1.36 |

| P1100HS | 20 | SS | 1.36 |

Beam Loading

| Beam Loading - P1100HS | ||||||

|---|---|---|---|---|---|---|

|

Span

(in) |

Max

Allowable Uniform

Load

(lbs) |

Deflection at

Uniform Load

(in) |

Uniform Loading at Deflection | Lateral Bracing Reduction Factor | ||

|

Span/180

(lbs) |

Span/240

(lbs) |

Span/360

(lbs) |

||||

| 24 | 1,215 | 0.06 | 1,215 | 1,215 | 1,215 | 1.00 |

| 36 | 810 | 0.13 | 810 | 810 | 630 | 0.89 |

| 48 | 612 | 0.23 | 612 | 531 | 360 | 0.78 |

| 60 | 486 | 0.36 | 459 | 342 | 225 | 0.68 |

| 72 | 405 | 0.51 | 315 | 234 | 162 | 0.59 |

| 84 | 351 | 0.70 | 234 | 171 | 117 | 0.52 |

| 96 | 306 | 0.92 | 180 | 135 | 90 | 0.47 |

| 108 | 270 | 1.15 | 144 | 108 | 72 | 0.43 |

| 120 | 243 | 1.42 | 117 | 81 | 54 | 0.40 |

| 144 | 207 | 2.09 | 81 | 63 | 36 | 0.36 |

| 168 | 171 | 2.75 | 54 | 45 | 27 | 0.32 |

| 192 | 153 | 3.67 | 45 | 36 | NR | 0.30 |

| 216 | 135 | 4.61 | 36 | 27 | NR | 0.28 |

| 240 | 126 | 5.90 | 27 | NR | NR | 0.26 |

| Note | NR - Not Recommended | |||||

Column Loading

| Column Loading - P1100HS | |||||

|---|---|---|---|---|---|

|

Unbraced Height

(in) |

Allowable Load at Slot Face

(lbs) |

Max Column Load Applied at C.G. |

|||

| K=0.65 (lbs) | K=0.80 (lbs) | K=1.0 (lbs) | K=1.2 (lbs) | ||

| 24 | 2,800 | 8,040 | 7,330 | 6,360 | 5,430 |

| 36 | 2,410 | 6,480 | 5,430 | 4,190 | 3,210 |

| 48 | 1,940 | 4,990 | 3,830 | 2,760 | 2,160 |

| 60 | 1,550 | 3,740 | 2,760 | 2,050 | 1,640 |

| 72 | 1,290 | 2,860 | 2,160 | 1,640 | 1,320 |

| 84 | 1,100 | 2,310 | 1,780 | 1,370 | 1,110 |

| 96 | 950 | 1,950 | 1,520 | 1,180 | 950 |

| 108 | 840 | 1,690 | 1,320 | 1,030 | KL/r>200 |

| 120 | 760 | 1,490 | 1,180 | KL/r>200 | KL/r>200 |

| 144 | 630 | 1,210 | 950 | KL/r>200 | KL/r>200 |

Elements of Section

| Elements of Section - P1100HS | ||

|---|---|---|

| Area of Section | 0.418 in2 (2.7 cm2) | |

| Axis 1-1 | Axix 2-2 | |

| Moment of Inertia (I) | 0.145 in4 (6 cm4) | 0.176 in4 (7.3 cm4) |

| Section Modulus (S) | 0.162 in3 (2.7 cm3) | 0.217 in3 (3.6 cm3) |

| Radius of Gyration (r) | 0.589 in (1.5 cm) | 0.65 in (1.7 cm) |

General Specifications

Standard Lengths:

- 10 feet: 10' or 10’ 1/8” (3.05m) ± 1/8" (3 mm)

- 20 feet: 20' or 20’ 3/8” (6.11m) ± 1/8" (3 mm)

Special Lengths:

- Available with a tolerance of ±1/8" (3 mm). Request quote.

Curved Channel:

- Many Unistrut channel sections can be supplied with a curve. Click here for our ordering form, specifications, and instructions.

Load Data:

- All beam and column load data pertains to carbon steel and stainless steel channels.

- Load tables apply only to UNISTRUT brand channel. Look for "UNISTRUT" on the product.

- Load tables and charts are constructed to be in accordance with the SPECIFICATION FOR THE DESIGN OF COLD-FORMED STEEL STRUCTURAL MEMBERS 2007 EDITION published by the AMERICAN IRON AND STEEL INSTITUTE USING ASD METHOD.

- Loads are based on 33 ksi steel cold formed to 42 ksi.

- Safety Factor to Yield Strength is 1.67 for Beam Loads and 1.80 for Column Loads.

- Beam loads are based on a simple beam and are given as a total uniform load (W) in pounds. For proper calculation procedures, refer to our Beam Load Calculation Guide.

- For bearing loads, reference our Bearing Loads Page.

Materials & Finishes

Materials & Finishes - Standard:

- Pregalvanized (PG): Conforms to ASTM A653 SS GR 33, G90.

- Unistrut Defender (DF): Conforms to ASTM A1046 SS GR 33

- Hot Dip Galvanized (HG): Steel conforms to ASTM A1011 SS GR 33, Finish conforms to ASTM A123

- Perma-Green (GR): Steel conforms to ASTM A1011 SS GR 33, E-Coat finish

- Perma-Gold (ZD): Steel conforms to ASTM A1011 SS GR 33, Finish conforms to ASTM B633, Type II SC3

- Plain (PL): Conforms to ASTM A1011 SS GR 33

- Stainless Steel, Type 304 (SS): ASTM A240, Type 304 *

- Stainless Steel, Type 316 (ST): ASTM A240, Type 316 *

- Aluminum (EA): ASTM B221, Type 6063-T6 (Extruded) *

* These materials have different physical properties and performance characteristics. Please contact us for design support.