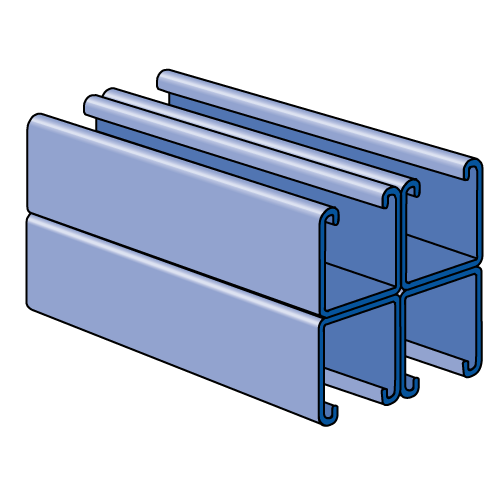

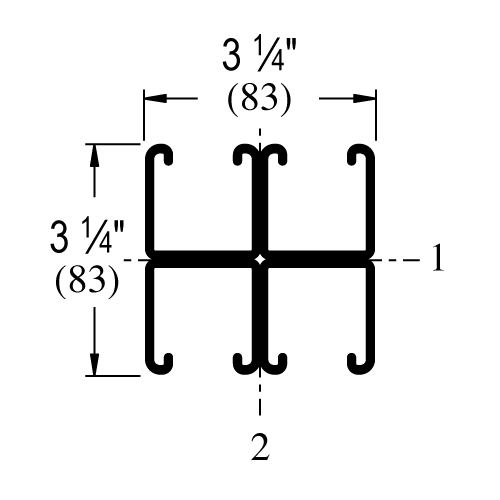

P1001C41 - 3-1/4" x 3-1/4", 12 Gage, Quadruple Combination

Unistrut's P1001C41 (quadruple combination), often known as 12 gauge standard or deep back-to-back strut channel, is commonly used for electrical supports, mechanical supports, pipe, conduit, duct and cable tray supports, and other general framing. For application examples, refer to our Application Showcase.

This channel is ideal because it provides additional loading capacity and multiple connection points on a single plane versus a double or triple combination.

Product dimensions are 3 1/4" Long x 3 1/4" Wide x 12 ga. thick; quadruple combination.

Our P1001C41 is available in the following finishes: Pre-Galvanized (PG), Hot-Dip Galvanized (HG), Plain (PL), Green (GR), Zinc Dichromate (ZD) and Stainless Steel (SS).

| Part No. | Length (ft) | Finish | Product Weight / Ft (lbs/ft) |

|---|---|---|---|

| P1001C41 | 20 | PG | 7.55 |

| P1001C41 | 10 | PG | 7.55 |

| P1001C41 | 10 | HG | 8.056 |

| P1001C41 | 20 | HG | 8.056 |

| P1001C41 | 20 | GR | 7.55 |

| P1001C41 | 10 | GR | 7.55 |

| P1001C41 | 20 | PL | 7.55 |

| P1001C41 | 10 | PL | 7.55 |

Beam Loading

| Beam Loading - P1001C41 | ||||||

|---|---|---|---|---|---|---|

|

Span

(in) |

Max

Allowable Uniform Load

(lbs) |

Deflection at Uniform load

(in) |

Uniform Loading at Deflection | Lateral Bracing Reduction Factor | ||

|

Span/180

(lbs) |

Span/240

(lbs) |

Span/360

(lbs) |

||||

| 24 | * 7,040 | 0.02 | * 7,040 | * 7,040 | * 7,040 | 1.00 |

| 36 | 6,380 | 0.07 | 6,380 | 6,380 | 6,380 | 1.00 |

| 48 | 4,790 | 0.13 | 4,790 | 4,790 | 4,790 | 1.00 |

| 60 | 3,830 | 0.20 | 3,830 | 3,830 | 3,240 | 1.00 |

| 72 | 3,190 | 0.28 | 3,190 | 3,190 | 2,250 | 0.98 |

| 84 | 2,740 | 0.39 | 2,740 | 2,480 | 1,660 | 0.95 |

| 96 | 2,390 | 0.50 | 2,390 | 1,900 | 1,270 | 0.93 |

| 108 | 2,130 | 0.64 | 2,000 | 1,500 | 1,000 | 0.90 |

| 120 | 1,910 | 0.78 | 1,620 | 1,220 | 810 | 0.87 |

| 144 | 1,600 | 1.14 | 1,130 | 840 | 560 | 0.82 |

| 168 | 1,370 | 1.55 | 830 | 620 | 410 | 0.77 |

| 192 | 1,200 | 2.02 | 630 | 480 | 320 | 0.72 |

| 216 | 1,060 | 2.54 | 500 | 380 | 250 | 0.67 |

| 240 | 960 | 3.16 | 410 | 300 | 200 | 0.62 |

| Note | *Load limited by weld shear | |||||

Column Loading

| Column Loading - P1001C41 | |||||

|---|---|---|---|---|---|

|

Unbraced Height

(in) |

Allowable Load at Slot Face

(lbs) |

Max Column Load Applied at C.G. |

|||

| K=0.65 (lbs) | K=0.80 (lbs) | K=1.0 (lbs) | K=1.2 (lbs) | ||

| 24 | 12,690 | 46,920 | 44,980 | 42,360 | 39,890 |

| 36 | 12,250 | 42,680 | 39,890 | 36,660 | 34,050 |

| 48 | 11,820 | 38,740 | 35,720 | 32,640 | 30,430 |

| 60 | 11,470 | 35,500 | 32,640 | 29,980 | 28,220 |

| 72 | 11,180 | 32,970 | 30,430 | 28,220 | 26,820 |

| 84 | 10,900 | 31,040 | 28,840 | 27,010 | 24,870 |

| 96 | 10,580 | 29,570 | 27,680 | 26,170 | 19,840 |

| 108 | 10,310 | 28,440 | 26,820 | 22,310 | 15,670 |

| 120 | 10,070 | 27,560 | 26,170 | 18,280 | 12,700 |

| 144 | 8,740 | 26,320 | 19,840 | 12,700 | 8,820 |

| 168 | 7,360 | 21,890 | 14,570 | 9,330 | KL/r>200 |

Elements of Section

| Elements of Section - P1001C41 | ||

|---|---|---|

| Area of Section | 2.221 in2 (14.3 cm2) | |

| Axis 1-1 | Axix 2-2 | |

| Moment of Inertia (I) | 1.856 in4 (77.3 cm4) | 2.408 in4 (100.2 cm4) |

| Section Modulus (S) | 1.142 in3 (18.7 cm3) | 1.482 in3 (24.3 cm3) |

| Radius of Gyration (r) | 0.914 in (2.3 cm) | 1.041 in (2.6 cm) |

General Specifications

Standard Lengths:

- 10 feet: 10' or 10’ 1/8” (3.05m) ± 1/8" (3 mm)

- 20 feet: 20' or 20’ 3/8” (6.11m) ± 1/8" (3 mm)

Special Lengths:

- Available with a tolerance of ±1/8" (3 mm). Request quote.

Curved Channel:

- Many Unistrut channel sections can be supplied with a curve. Click here for our ordering form, specifications, and instructions.

Load Data:

- All beam and column load data pertains to carbon steel and stainless steel channels.

- Load tables apply only to UNISTRUT brand channel. Look for "UNISTRUT" on the product.

- Load tables and charts are constructed to be in accordance with the SPECIFICATION FOR THE DESIGN OF COLD-FORMED STEEL STRUCTURAL MEMBERS 2007 EDITION published by the AMERICAN IRON AND STEEL INSTITUTE USING ASD METHOD.

- Loads are based on 33 ksi steel cold formed to 42 ksi.

- Safety Factor to Yield Strength is 1.67 for Beam Loads and 1.80 for Column Loads.

- Beam loads are based on a simple beam and are given as a total uniform load (W) in pounds. For proper calculation procedures, refer to our Beam Load Calculation Guide.

- For bearing loads, reference our bearing loads page.

Welds:

- Welded channels are spot welded 2" (51 mm) or 3" (76 mm) on-center.

Materials & Finishes

Materials & Finishes - Standard:

- Pregalvanized (PG): Conforms to ASTM A653 SS GR 33, G90.

- Unistrut Defender (DF): Conforms to ASTM A1046 SS GR 33

- Hot Dip Galvanized (HG): Steel conforms to ASTM A1011 SS GR 33, Finish conforms to ASTM A123

- Perma-Green (GR): Steel conforms to ASTM A1011 SS GR 33, E-Coat finish

- Perma-Gold (ZD): Steel conforms to ASTM A1011 SS GR 33, Finish conforms to ASTM B633, Type II SC3

- Plain (PL): Conforms to ASTM A1011 SS GR 33

- Stainless Steel, Type 304 (SS): ASTM A240, Type 304 *

- Stainless Steel, Type 316 (ST): ASTM A240, Type 316 *

- Aluminum (EA): ASTM B221, Type 6063-T6 (Extruded) *

* These materials have different physical properties and performance characteristics. Please contact us for design support.