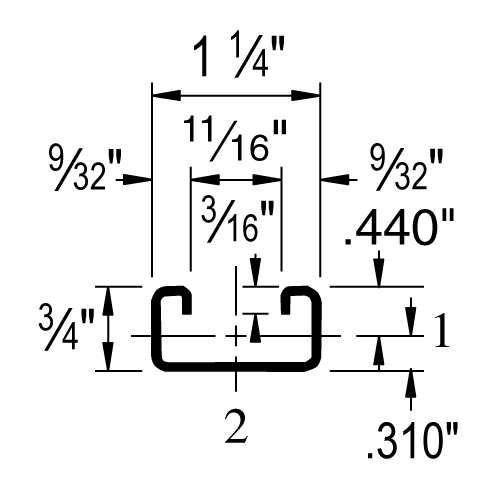

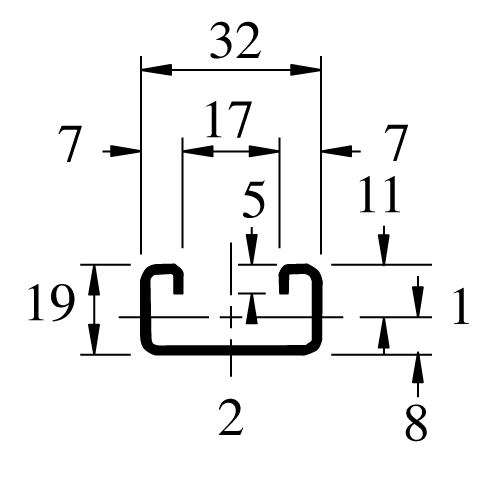

A3300 - 1-1/4" x 3/4", 14 Gage Channel

| Part No. | Length (ft) | Finish | Product Weight / Ft (lbs/ft) |

|---|---|---|---|

| A3300 | 20 | PG | 0.78 |

| A3300 | 10 | PG | 0.78 |

| A3300 | 20 | GR | 0.78 |

| A3300 | 10 | GR | 0.78 |

| A3300 | 10 | PL | 0.78 |

| A3300 | 20 | PL | 0.78 |

Beam Loading

| Beam Loading - A3300 | ||||||

|---|---|---|---|---|---|---|

|

Span

(in) |

Max Allow. Uniform Load

(lbs) |

Deflection at Uniform Load

(in) |

Uniform Loading at Deflection | Lateral Bracing Reduction Factor | ||

|

Span/180

(lbs) |

Span/240

(lbs) |

Span/360

(lbs) |

||||

| 18 | 420 | 0.07 | 420 | 420 | 320 | 1.00 |

| 24 | 320 | 0.12 | 320 | 270 | 180 | 1.00 |

| 36 | 210 | 0.26 | 160 | 120 | 80 | 0.97 |

| 48 | 160 | 0.47 | 90 | 70 | 50 | 0.94 |

| 60 | 130 | 0.75 | 60 | 40 | 30 | 0.91 |

| 72 | 110 | 1.09 | 40 | 30 | 20 | 0.89 |

| 84 | 90 | 1.42 | 30 | 20 | 10 | 0.87 |

| 96 | 80 | 1.88 | 20 | 20 | 10 | 0.85 |

Column Loading

| Column Loading - A3300 | |||||

|---|---|---|---|---|---|

|

Unbraced

Height (in) |

Allowable

Load at Slot Face (lbs) |

Max Column Load Applied at C.G. | |||

| K=0.65 (lbs) | K=0.80 (lbs) | K=1.0 (lbs) | K=1.2 (lbs) | ||

| 18 | 1,430 | 4,490 | 4,210 | 3,860 | 3,550 |

| 24 | 1,370 | 4,090 | 3,750 | 3,310 | 2,680 |

| 36 | 1,190 | 3,390 | 2,680 | 1,820 | 1,260 |

| 48 | 900 | 2,380 | 1,600 | 1,020 | KL/r>200 |

| 60 | 680 | 1,550 | 1,020 | KL/r>200 | KL/r>200 |

Elements of Section

| Elements of Section - A3300 | ||

|---|---|---|

| Area of Section | 0.23 in2 (1.5 cm2) | |

| Axis 1-1 | Axix 2-2 | |

| Moment of Inertia (I) | 0.017 in4 (0.7 cm4) | 0.052 in4 (2.2 cm4) |

| Section Modulus (S) | 0.038 in3 (0.6 cm3) | 0.083 in3 (1.4 cm3) |

| Radius of Gyration (r) | 0.269 in (0.7 cm) | 0.477 in (1.2 cm) |

General Specifications

Standard Lengths:

- 10 feet: 10' or 10’ 1/8” (3.05m) ± 1/2" (13 mm)

- 20 feet: 20' or 20’ 3/8” (6.11m) ± 1/2" (13 mm)

Load Data:

- All beam and column load data pertains to carbon steel and stainless steel channels.

- Load tables apply only to UNISTRUT brand channel. Look for "UNISTRUT" on the product.

- Load tables and charts are constructed to be in accordance with the SPECIFICATION FOR THE DESIGN OF COLD-FORMED STEEL STRUCTURAL MEMBERS 2007 EDITION published by the AMERICAN IRON AND STEEL INSTITUTE USING ASD METHOD.

- Loads are based on 33 ksi steel cold formed to 42 ksi.

- Safety Factor to Yield Strength is 1.67 for Beam Loads and 1.80 for Column Loads.

- Beam loads are based on a simple beam and are given as a total uniform load (W) in pounds. For proper calculation procedures, refer to our Beam Load Calculation Guide.

- For bearing loads, reference our bearing loads page.

Welds:

- Welded channels are spot welded 2" (51 mm) or 3" (76 mm) on-center.

Materials & Finishes

Materials & Finishes - Standard:

- Pregalvanized (PG): Conforms to ASTM A653 SS GR 33, G90.

- Unistrut Defender (DF): Conforms to ASTM A1046 SS GR 33

- Hot Dip Galvanized (HG): Steel conforms to ASTM A1011 SS GR 33, Finish conforms to ASTM A123

- Perma-Green (GR): Steel conforms to ASTM A1011 SS GR 33, E-Coat finish

- Perma-Gold (ZD): Steel conforms to ASTM A1011 SS GR 33, Finish conforms to ASTM B633, Type II SC3

- Plain (PL): Conforms to ASTM A1011 SS GR 33

- Stainless Steel, Type 304 (SS): ASTM A240, Type 304 *

- Stainless Steel, Type 316 (ST): ASTM A240, Type 316 *

- Aluminum (EA): ASTM B221, Type 6063-T6 (Extruded) *

* These materials have different physical properties and performance characteristics. Please contact us for design support.